At Hidral we know that an elevator is not just a machine: it is a strategic investment. That is why, when we talk about modernisation, we do not do it from the urgency, but from the opportunity. Modernising is not simply replacing components, but anticipating the future. It is a commitment to safety, efficiency and performance, with tailor-made solutions designed to extend the useful life of each piece of equipment.

In the elevation sector, the modernisation of equipment has become a necessity to guarantee safety, efficiency and durability. At Hidral, we understand that each lift is a long-term investment and, therefore, we offer modernisation solutions adapted to the real needs of the end customer.

Why modernise an elevator?

With the passage of time, the lifting systems may show signs of wear and tear, become technologically or regulatory obsolete, or simply no longer meet current safety and efficiency standards.

In addition to extending the life of the equipment, retrofitting brings a number of key benefits:

- Increased securityUpgrading essential components reduces the risk of failure and improves the protection of users and goods.

- Better user experience: More intuitive interfaces, smoother movements and greater accessibility provide differential value to the end user.

- Long durability: Recurring breakdowns are avoided and performance is optimised for years to come.

- More efficient maintenance: The integration of remote diagnostics facilitates preventive management and reduces downtime.

- Regulatory adaptation: Complies with current regulations without the need to replace the entire lifting system.

How we approach modernisation at Hidral

Our approach is based on active listening, technical innovation and continuous improvement. Each modernisation process stems from a real analysis of the client's needs, with a structured and collaborative methodology:

- Direct contact with customers: Our after-sales and engineering teams work closely with lift operators to identify critical points for improvement. These conversations allow us to gather suggestions, detect recurring incidents and prioritise real needs.

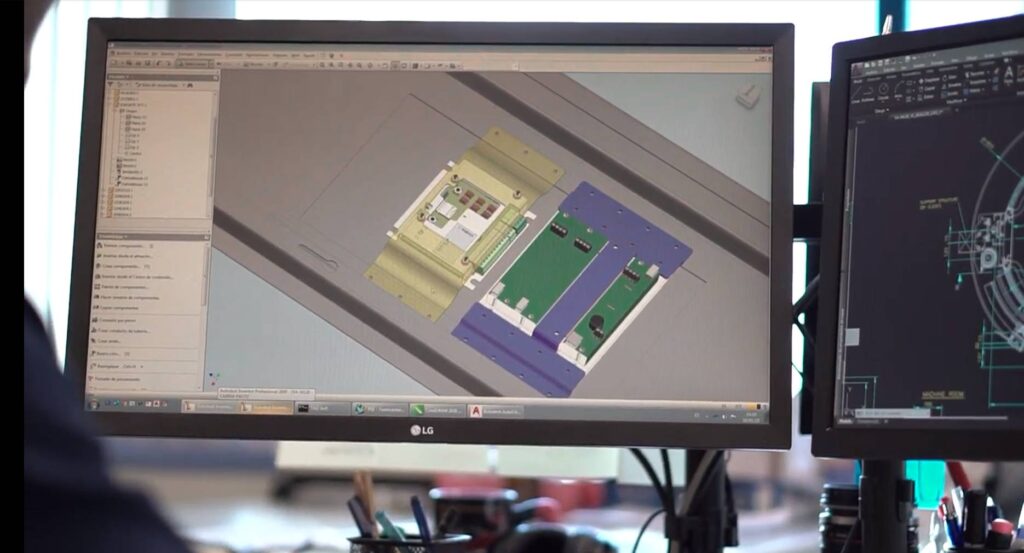

- Data analysis and opportunity identification: From the information gathered, we carry out a detailed technical study of the installed equipment. We identify wear patterns, common breakdowns and areas where technology can add value.

- Development of solutions together with strategic clients: We work with selected customers to implement pilot enhancements in real-world environments. This testing phase allows us to validate the effectiveness of each solution, fine-tune it and optimise it before its general deployment.

- Implementation and continuous monitoring: Once validated, the solution is implemented on a large scale. But our commitment does not end there. We also constantly monitor to ensure that each improvement works as expected and make further adjustments, if necessary.

Tangible results and constant evolution

Modernisation in Hidral is a constant process of evolution. Thanks to our bidirectional approach with the customer, we have incorporated improvements that not only optimise the operation of the elevators, but also open new lines of innovation within our R+D+i department.

Improvements implemented to date include:

- Trolley restraint systems that improve safety and efficiency in the movement of goods.

- Advanced control systems allow for more precise regulation of the equipment.

- Remote control integration to facilitate faster and more efficient maintenance.

- Improved accessibility solutions, designed to offer a more comfortable, safe and universal user experience.

At Hidral, we believe that modernisation is key to staying at the forefront of the lifting sector. Our commitment to continuous improvement allows us to offer practical and effective solutions, adapted to the real needs of our customers.

Because manufacturing elevators is just the beginning. Keeping them up to date and in top condition is what guarantees their future.