There is something magnetic about watching the future being built. In Hidral's industrial buildings, that magnetism is felt in every corner: in the sound of precision-moulded steel, in the orchestrated movement of parts that end up fitting into a perfect gear, and in the certainty that every elevator that leaves its factories bears the stamp of a job well done.

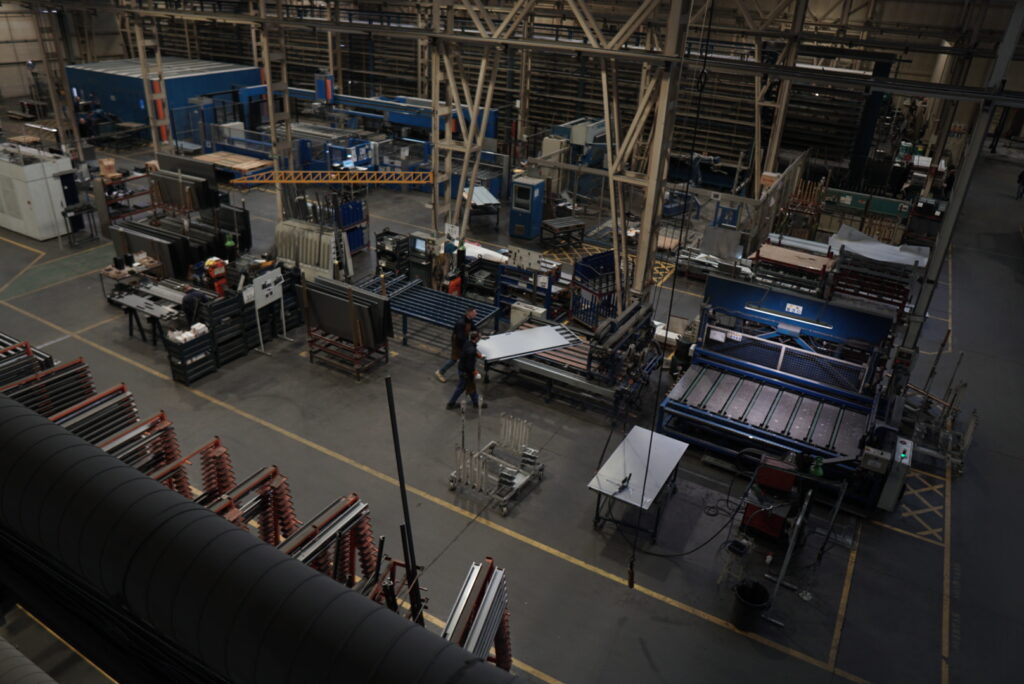

Located in Seville, Hidral has more than 28,000 square metres of industrial space spread over two floors. From here, lifting equipment is manufactured that travels to more than 120 countries, transforming spaces, making buildings accessible and facilitating the daily lives of thousands of people. But behind this global figure, there is a local story: that of a team that, for 50 years, has continued to believe that quality is made piece by piece, without shortcuts.

The journey begins in the detail

Every project at Hidral starts long before the first piece goes into production. The first step is in the raw material: carefully selected materials that go through a rigorous quality control at the time of receipt. This is the only way to ensure that everything built thereafter meets the high standards demanded by the brand.

From there, the process continues with exemplary coordination between the engineering, technical sales and production departments. Customisation is a constant. Thanks to the work of the R&D&IWith more than 25 people, each team is designed with the specific needs of the project and the client in mind. No two solutions are the same, because no two buildings, no two uses and no two people are the same.

All this knowledge is transformed into robust, reliable and precise products that are capable of integrating into industrial, residential or commercial environments with equal efficiency. And all this without losing sight of a principle that runs through everything: every metre counts.

Manufacturing only for professionals, manufacturing without compromises

Hidral is fully committed to a B2B model. Here we manufacture complete equipment for the professional lifter. This implies an absolute commitment to the installer, who knows that by trusting Hidral he receives a product ready to be installed, adapted to the particularities of the project, and accompanied by a technical team that is present before, during and after.

The result is a line of products that ranges from industrial forklifts to high-capacity lifts and solutions for accessibilityall with the same philosophy: design and manufacture without compromising quality, safety or aesthetics.

This model, sustained with a clear long-term vision, has enabled 70% of Hidral's production to be exported to international markets. Our own branches in France, Italy, the United Kingdom, the Middle East and Russia consolidate a global presence which has continued to grow, always faithful to its original values.

One team, one vision, one story that is still going on.

Hidral's soul is not only in its products, but in the people who make them possible. From plant operators to engineers, from logistics to administration, they all work towards a common goal: that every piece of lifting equipment that leaves the facility works perfectly from day one... and for many years to come.

The coordination between departments is millimetric. Each order is a project, and each project has a name, a history and a destination. That is why after-sales service and technical follow-up are not optional, but an essential part of the service. Because Hidral's commitment to its customers does not end with the delivery of the equipment: it only changes phase.

After five decades of experience, Hidral continues to look forward, with the same enthusiasm of its beginnings, but with the maturity that comes from experience, constant innovation and a consolidated global network. To visit its plant is to understand how excellence is manufactured, day after day, from Seville to the world.